I got my qwiic conector cables and the device worked immediately. The hex package currently depends on I2C 1.x so I have to override that to 2.x which seems to work fine.

I was able to set a configuration and read some values, but I have no idea how to interpret the values I got back so far

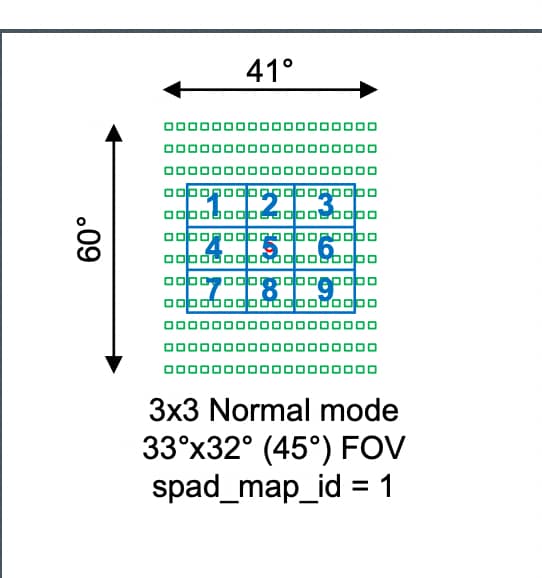

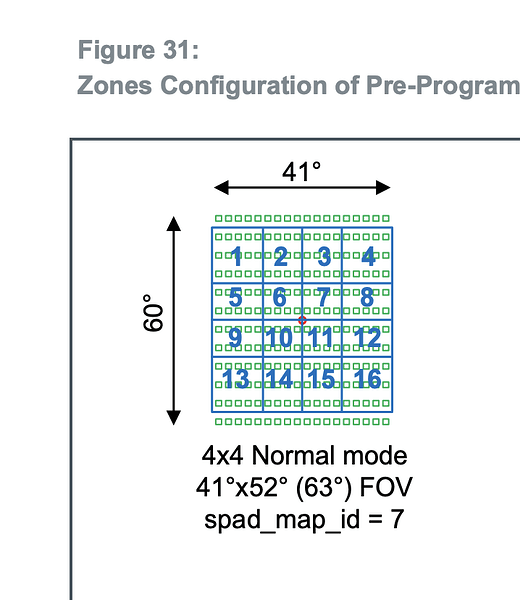

iex(14)> config = TMF882X.get_config(pid) |> Map.put(:spad_map_id, 7)

%{

period: 33,

alg_setting_0: %{distances: true, logarithmic_confidence: false},

confidence_threshold: 6,

gpio_1: %{gpio: 0, driver_strength: 0, pre_delay: 0},

gpio_2: %{gpio: 0, driver_strength: 0, pre_delay: 0},

hist_dump: false,

i2c_addr_change: 0,

i2c_slave_address: 65,

int_persistence: 0,

int_threshold_high: 65535,

int_threshold_low: 0,

int_zone_mask_0: 0,

int_zone_mask_1: 0,

int_zone_mask_2: 0,

kilo_iterations: 537,

osc_trim_value: 12,

power_cfg: %{

allow_osc_retrim: false,

goto_standby_timed: false,

keep_pll_running: false,

low_power_osc_on: false,

pulse_interrupt: false

},

spad_map_id: 7

}

iex(15)> TMF882X.put_config(pid, config)

:ok

iex(16)> config.spad_map_id

7

iex(17)> TMF882X.start_measuring(pid)

:ok

iex(18)> TMF882X.stop_measuring(pid)

:ok

iex(19)> flush()

{:tmf882x,

%TMF882X.Result{

tid: 241,

size: 128,

number: 237,

temperature: 20,

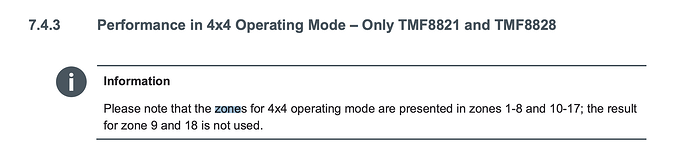

valid_results: 23,

ambient: 6502,

photon_count: 1657586,

reference_count: 56528,

sys_tick: 124164633,

measurements: [

{101, 255},

{100, 255},

{104, 255},

{115, 255},

{118, 255},

{113, 255},

{113, 255},

{116, 255},

{0, 0},

{110, 255},

{109, 255},

{110, 255},

{113, 255},

{119, 255},

{117, 255},

{113, 255},

{112, 255},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{0, 0},

{545, 56},

{563, 62},

{582, 31},

{590, 109},

{586, 255},

{601, 255},

{625, 98},

{0, 0}

]

}}